Journal of Food Science and Nutrition Therapy

Shelf life extension for yogurt production in circumstances of regular power outages - Eritrean Yogurt Study

SJ Schneeberger1*, N Madgwick2, L Schotter3, U Rohrs Ameen4 and G Kasozi3

2Neil Madgwick Science Consultancy, South Africa

3GI Science Solutions, South Africa

4Time for Sense, South Africa

Cite this as

Schneeberger SJ, Madgwick N, Schotter L, Ameen UR, Kasozi G (2024) Shelf life extension for yogurt production in circumstances of regular power outages - Eritrean Yogurt Study. J Food Sci Nutr The 10(1): 001-008. DOI: 10.17352/jfsnt.000045Copyright

© 2024 Schneeberger SJ, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.Due to many parts of Africa suffering from interrupted electrical supply, and hence a broken cold chain, a solution for shelf life extension for perishable foods is needed. An industry that is one of the hardest hit and in most need of shelf life extension is the dairy industry - in particular during yogurt production. It is anticipated that resolving the issue of interrupted electrical supply is improbable in the near future.

In Eritrea, yogurt production is at ambient temperatures – approximately 28 oC. After production, the yogurt will go into the fridge with a view to being sold the next day. Electricity supply is unpredictable and can be disrupted for 6 – 12 hours a day.

The aim of this study was to determine if the shelf life of yogurt produced in Eritrea under these less-than-ideal conditions could be improved by using natural additives.

This study showed that the use of Codex Alimentarius-approved ingredients (native starch, mTGase, Natamycin, and Nisin) when added to the yogurt in the presence of a regularly interrupted electrical supply, produced microbiologically and organoleptically stable yogurt for up to 28 days.

Introduction

The origins of yogurt production date back approximately 5,000 years. In all likelihood, the accidental contamination of milk from domesticated animals leads to the spontaneous fermentation of the milk, giving rise to yogurt. While there is evidence of yogurt in the diets of the peoples of Asia and Mesopotamia, it is possible that yogurt was discovered independently by different peoples around the same time, in different places around the world [1-3].

No record was found of when yogurt production and consumption began in Eritrea. It can be assumed that the colonization of Eritrea brought with it Italian cuisine, which would have included yogurt [4]. Yogurt production in Eritrea faces many challenges – intermittent supply of milk interrupted electrical supply that impacts the ability to adequately chill yogurt following fermentation, and a short supply of cleaning materials, to name a few. According to the World Bank website, in 2021 only 52.5% of Eritreans had access to electricity [5]. On the African Union website, it was mentioned that “Eritrea is facing acute shortages of modern energy services, especially in rural areas, and the country is generally characterized by low energy consumption levels.” [6].

Eritreans belong predominantly to the Orthodox Coptic Church. Out of the 365 days of the year, Copts are known to fast intermittently for between 210 to 240 days. Coptic fasting means adhering to a vegan diet, thus abstaining from meat, fish, eggs, dairy, and other animal products [7,8]. Instead, food made of fava beans, lentils, grape leaves, tomatoes, potatoes, etc. is consumed during fasting days [9]. This means that Copts abstain from all animal products for up to two-thirds of each year [7,8].

Eritrean processors battle to achieve reasonable shelf life in yoghurt. Personal communication with yogurt producers in Eritrea indicates that a shelf life of only 5-7 days is achievable. During fasting periods, this results in a high level of wastage.

The short shelf-life of Eritrean yogurt can be attributed to various factors: interrupted electrical supply, hindering both the incubation and chilling process of yoghurt; lack of shelf-life extenders; no starch stabilisers or high shear equipment available; poor or broken cold chain for distribution to outlets; poor or no access to constant refrigeration by consumers. These factors contribute to the rapid spoilage of Eritrean yogurt.

In Eritrea, yogurt production is at ambient temperatures – approximately 28 oC. After production, the yogurt is refrigerated with a view to being sold the next day. However, Seth [10] reports that “[the] country has major deficiencies in energy supply.” More recently, The African Development Bank Group [11] reports that “Eritrea experiences inadequate, unreliable, expensive and polluting electricity supply. The available capacity is 35 MW for a peak demand of about 70 MW. Consequently, frequent load-shedding periods affect businesses and the population.”

In many parts of Africa, where the supply of a constant, reliable source of electricity is unavailable, it is predicted that this problem is unlikely to be solved in the foreseeable future. It is reported on the African Infrastructure Knowledge Program website that “[in] Sub-Saharan Africa, just one person in five has access to electricity. If current trends continue, fewer than 40 percent of African countries will reach universal access to electricity by 2050.” Furthermore, it is pointed out that “Frequent power outages mean big losses in forgone sales and damaged equipment.”

Given the above challenges, any reasonable interventions that result in shelf life extension of yogurt would provide improved yogurt quality, improved food safety, and reduced waste.

It has been shown that the addition of starch to yogurt provides improved texture and mouthfeel, particularly in low-fat/skimmed milk yogurt [12].

Bio-preservatives are compounds produced by a living microorganism. Examples include nisin and natamycin.

According to Sreeramya, et al. [13], nisin is a bacteriocin (lantibiotic) produced by certain strains of Lactococcus lactis ssp. lactis which has been widely used as a food preservative for more than 60 years. The authors also point out that the USFDA classifies nisin as GRAS (Generally Recognized as Safe) and that in milk and milk products, nisin is used at levels ranging from 1-25 ppm.

Sreeramya, et al. further state that “Natamycin, also known as pimaricin, is a macrolide polyene antifungal agent that is produced by Streptomyces natalensis. It is especially active against yeasts and moulds. It has been used in cheese to control spoilage by fungi. Its minimum inhibitory concentration is less than 10 ppm for most moulds.”

Both nisin and natamycin are listed in Codex Alimentarius for use in dairy products [14].

According to current literature, the crosslinking of milk proteins by microbial transglutaminase (mTGase) increases the viscosity of yogurt gel and reduces the occurrence of syneresis [15].

This study explored the addition of native starch (tapioca), nisin, natamycin, and microbial transglutaminase in yogurt stored under varying electricity supply conditions, resulting in prolonged periods of time when refrigeration was switched off.

Materials and methods

Equipment and materials

The following equipment and materials were used to perform the trial:

- 20-litre stainless-steel pot

- Whisk (stainless steel)

- “Green Soap” (household dish detergent)

- Bleach water (30ml chlorine bleach in 5 litres of water)

Before the utensils were used in the trial, they were washed with “green soap”, rinsed with bleach water, and allowed to dry.

The following ingredients (with their sources in parentheses) were used to make the yogurt:

- Milk (full fat, local retail store)

- BM 834 Starch (Q&A Ingredient Solutions, South Africa)

- Nisin (Silver Elephant, China)

- Natamycin (Silver Elephant, China)

- mTGase (McCullum, South Africa)

- Yogurt Culture (Chr Hansen, South Africa).

Methodology

A 20-litre pot was used to make a 10 kg batch of yogurt according to the recipe provided by Time for Sense (Appendix I). This is the same yogurt production method used in Eritrea. The 10 kg batch was split into two 5 kg amounts - one for the Control samples and the other for Trial samples.

Control samples were incubated for three hours at 38 oC, allowed to cool for four hours, and placed in the fridge (8oC) overnight.

The Trial samples took longer to set, requiring six and a half hours of incubation at 38 oC. These samples were allowed to cool for four hours and then placed in the fridge (8 oC) overnight.

The incubation and cooling times were chosen based on the procedures used by the Eritreans in their yogurt-making protocol. It was decided to emulate these as closely as possible.

The trial was run for a total of 4 weeks, with various tests being conducted at predetermined times. For each of the Control and Trial arms of the investigation, 5 samples, each of 50g, were prepared per off-take (resulting in a total of 20 tests for each of the Trial and Control over the course of the four weeks). The various off-takes were tested for microbial activity - in particular Lactobacillus sp. (LAB), yeast and moulds, Escherichia coli and Staphylococcus aureus - physical parameters pH, syneresis information and temperature, and lastly visual and organoleptic properties.

Monitoring temperatures

Loadshedding is implemented in Africa when the electricity demand exceeds supply and is likely to cause the power grid to collapse. Often, the electrical supply to various areas is shut off according to a pre-set schedule.

The test kitchen fridge was switched off for eight hours per day – from 8 am to 4 pm, as part of the planned electricity disruption for the study. In addition, load shedding (Level 4) also took place during the trial. Over and above the load shedding, there were two additional episodes of unplanned power outages, resulting in longer periods when the fridge was off.

A mercury thermometer was placed inside the fridge, just in front of the shelves. The probe of an electronic thermometer (STC 1000) was placed towards the back of the fridge.

The mercury and electronic thermometers were calibrated with ice water and steam. The venue where the test kitchen is situated is 327m above sea level (Android App - Altitude Meter - Altimeter App).

Microbiological testing

Samples were prepared on a Thursday (Day 0). Microbiology testing was conducted on Days 7, 14, 21 & 28. (Table 1).

In addition to testing the samples at the scheduled offs-takes, the following tests were conducted using Praecautio in-house hygiene monitoring swabs on Day 0, ahead of sample preparation. This was to ensure that there was no contamination potential from the equipment and milk used. (Table 2).

Physical parameters monitored

For each of the 5 Control and 5 Trial samples, the following physical tests were conducted on days 4, 7, 11, 14, 21, and 28.

- pH and syneresis information

- Temperature

pH: pH testing was conducted using a pH meter (Tester family Hanna pH Meter Tester Model HI98107). The meter was standardised against pH 4.0 and pH 7.0 solutions (pH standard solutions obtained from Minema Laboratory Supplies, South Africa).

Syneresis:

Syneresis information was obtained by using the following method:

- A clean piece of kitchen paper towel was used for each determination, weighed, and recorded.

- The paper towel was placed in a clean sieve, and both were then placed in a clean stainless-steel bowl.

- The bowl was placed on a scale and tared.

- The yogurt was placed on the paper in the sieve, weighed, and left to stand at ambient temperature for 1 hour.

- The mass of the liquid in the bowl (after 1 hour) was recorded.

- The yogurt on the paper towel was scraped off. Care was taken to make sure there was no yogurt left on the paper towel.

- The mass of the wet paper towel was then recorded, and the amount of water retained by the paper was calculated.

The percentage (%) syneresis was then calculated from the above data using the following formulae:

Lpt = Mpta - Mptb

Where:

Lpt = mass of the liquid in paper towel

Mpta = the mass of paper towel after the procedure

Mptb = the mass of paper towel before the procedure

Ltot = Lpt + Lb

Where:

Ltot = the total mass of the liquid in the yogurt sample

Lb = the total mass of the liquid in the bowl after 1 hour of draining through the paper towel

S = (Ltot / Ytot) x 100

Where:

S = % syneresis

Ytot = total mass of the yogurt before the procedure

Evaluation of visual and organoleptic properties

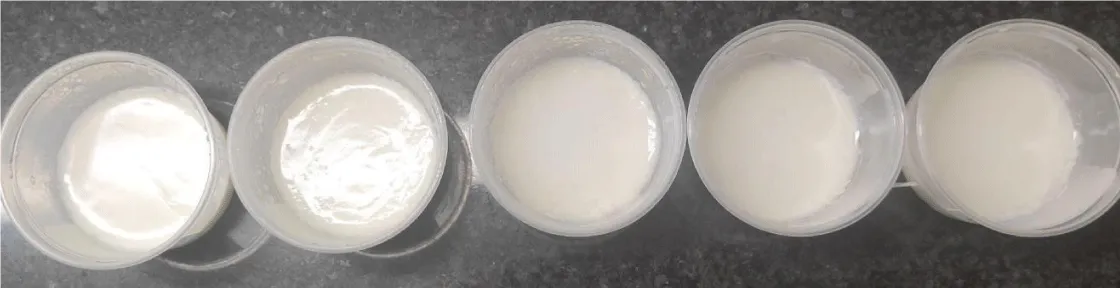

In addition to the 5 x 50g Control & Trial samples, 300 g tubs of yogurt samples were made. This is the format that is most common in Eritrea. These 300g tubs were used to conduct the visual and organoleptic tests.

For each of the organoleptic components, 5 trial and 5 control samples were tested per off-take.

The following three people conducted the organoleptic testing: Dr. SJ Schneeberger (62-year-old male), L Schotter (52-year-old female), and U Rohrs Ameen (50-year-old female).

Photographs were taken as a record of the visual changes in the Control and Trial samples. A sensory lexicon, as described by Coggins, et al. [16], was used to standardise taste information. All tasters were trained in the use of the lexicon with the aim of standardizing the sensory evaluation. The lexicon was applied consistently at each sensory evaluation.

Results

Temperature monitoring

Table 3 shows the daily temperature readings as well as the factors, other than the scheduled electricity interruptions, that influenced these readings. The temperature records shown in the table show that during the trial, only three readings were 8.0 oC, with the rest being over the ideal range of 2-8 oC. The highest temperature recorded was 20.5 oC.

Microbiological testing

With respect to the results for Yeasts and Moulds, there was a marked difference between the microbial growth of the Control versus the Trial samples in samples tested on Day 14 and Day 21. With respect to the Day 14 samples, the Control showed high numbers of yeasts and moulds, whereas the Trial showed less than the lowest detectable value for the test conducted. The same result was seen in the Day 21 samples - with high yeast and mould counts versus less than the detectable value for the Control and the Trial respectively. The Day 28 samples showed that the yeast and moulds in the Trial samples continued to be suppressed.

The results from the Lactobacillus (LAB) assays for samples taken on Day 7 showed that there were less than the lowest detectable number of colony-forming units (CFU/g) except for one of the Trial samples. The assay run had 1000 CFU/g as the lowest detectable quantity detected. One of the trial samples was not less than 1000 CFU/g which implies that the counts for the other samples would have been close to 1000 CFU/g.

Because the results obtained on Day 7 for the LAB mostly showed less than the minimum detectable level on Day 14 and Day 21, the dilution used in the assay was adjusted so that the lowest detectable level was 100 CFUs/g. The results showed that in all the Trial and Control samples for both the Day 14 and Day 21 off-takes, all samples returned results of less than 100 CFU/g.

On Day 28, the LAB results showed a marked increase for the Trial samples, with some samples showing higher than the detectable upper limit, and others showing within the 10,000 CFU/g. The Control samples were not tested microbiologically on Day 28 as they were deemed to have too much growth based on visual appearance.

The results from the pre-checks of equipment and milk to ensure sterility before testing began (conducted using Praecautio in-house swab tests) were all negative for bacterial contamination.

Results from contamination tests of the yogurt samples on Day 28 (conducted using Praecautio in-house swab tests) returned negative results for Escherichia coli for both Control and Trial samples, and negative results for Staphylococcus aureus for the Trial samples. The Control samples showed some contamination on the Praecautio Staph aureus swabs which indicated contamination from a gram-positive bacterium/bacteria species other than S.aureus.

Physical parameters monitored

Table 4 shows the pH readings taken during the trial, and Table 5 shows the percentage of syneresis that occurred in both the Control and Trial yogurt samples.

Visual and organoleptic assessment

For both the trial and control samples, taste, aroma, texture, and appearance were recorded on Day 2, Day 4, and every 4th day after that until Day 28 (Figures 1,2). Compared to the Control samples, which were fully developed from the first tasting, the trial samples were slower in developing full flavours and aroma. The taste and other attributes of the Trial samples were essentially unchanged until Day 28 when the taste became somewhat tart.

The Control yogurt was fully developed from the start. Tart notes were tasted on Day 11. Small amounts of mould were noted on Day 14 with off flavours and smells noted. No further evaluation was conducted from day 14 onwards due to the growth of mould in the sample.

Discussion

Temperature

A significant factor that is responsible for the short shelf life of yogurt in Eritrea is the lack of a constant supply of electricity, this is due to the fact that it has “acute shortages of modern energy services” [6]. This results in unpredictable and below-acceptable refrigeration conditions. The trial was set up to replicate, as close as possible, the conditions that yogurt producers in Eritrea face in terms of refrigeration challenges.

As stated by Jakubowska M and Karamucki T [17], “[the] recommended storage temperature of yoghurt ranges from 1°C to 8°C, but its durability may be enlarged by storing at 4°C or less during the whole shelf life.” At the temperatures recorded, the shelf life of the yogurt would have been adversely affected, with conditions for spoilage being favourable. It can therefore be assumed that any shelf life extension would be because of the direct influence of the additives added during the trial.

Microbiology results

Yeast and mould results: The overall results showed that the growth of yeasts and moulds was suppressed in the trial samples right until the end of the 28-day trial period. The trends shown in these results can be directly attributed to the addition of natamycin and nisin in the Trial samples. As noted, by Sreeramya, et al. [13], natamycin is “especially active against yeasts and molds” and “[it] has been employed in dairy-based food products to control spoilage by fungi”. The same authors mention that “[Nisin] helps in preventing… white mold”. Furthermore, Var, et al. [18] showed that “after 30 [days] of storage, no growth of moulds and yeasts were detected in the presence of natamycin”. Based on these references and the prolific growth of yeast and moulds in the Control (which did not have these antimicrobials added to it), it can be concluded that the addition of natamycin and nisin to the Trial samples suppressed the growth of yeast and moulds for the full length of the trial.

LAB results: The results for the Trial, as well as the Control, up until day 21, were all less than 100 CFU/g. This indicates that the LAB was suppressed - which is desirable at this point in the timeline so as to prevent the “tangy, sour” taste that results in an over-fermented yogurt. This result is consistent with the results found by Var, et al. [18] where “the population of yogurt bacteria decreased approximately 3 log cycles in 30 [days]”.

On Day 28, the LAB results showed a marked increase. This was confirmed in the taste tests in which the “tangy/sour” taste was detected. There are two possible causes of this sudden increase - an external contaminant, or a resurgence of the LAB due to it being subdued but not eliminated from the yogurt.

The levels of nisin included in the yogurt are according to international standards, and also low enough to allow the LAB to ferment the milk to create yogurt. After initial fermentation, as has been discussed, the concentration of LAB decreased. However, it is a possibility that over time, the nisin was less effective in controlling the continued growth of the LAB. Ogden, [19] noted that “Depending on the amount used and the strain of bacteria involved, nisin either kills lactic acid bacteria or inhibits their growth.” Budd and Jakobsen [20] noted that “immobilized cells were significantly less sensitive to nisin than planktonic cells.” There is therefore evidence that LAB cells can continue to be viable in yogurt and it is possible that over time a resurgence of LAB is possible.

Unfortunately, it could not be determined whether the increase in LAB on day 28 was due to a contaminant or the resurgence of the original LAB culture used.

Other contaminants: Apart from controlling the excess growth of LAB, yeast, and moulds in the yogurt production process, other contaminants of yogurt also need to be monitored and controlled. Obende (1999), as cited by Makut, et al. [21], notes “In countries where foodborne illnesses are investigated and documented, the relative importance of pathogens like Staphylococcus aureus and Escherichia coli in yoghurt borne infection is well known.” Nisin is effective in controlling the growth of gram-positive bacteria. Sreeramya, et al. [13] note that nisin “...exhibits antibacterial activity against a wide range of Gram-positive bacteria and was particularly effective against bacterial spores”, and Li, et al. [22] suggest that nisin is highly effective against gram-positive bacteria.

The contaminants apart from yeasts and moulds were monitored by checking with Praecautio’s in-house hygiene monitoring swabs. Praecautio swabs give a qualitative result based on a chromogenic reaction. Although it is not possible to check for every possible microbiological contaminant, the Praecautio swabs were used as an indicator of the sterility of the equipment before the trial began. This ensured the validity of the trial.

Two types of Praecautio swab were used - E. coli and S. aureus. The E. coli swab turns blue/green in the presence of E.coli, but other gram-negative organisms also show a discolouration, other than blue/green, of the growth medium. The S. aureus swab shows a pink discolouration of the medium in the presence of S. aureus but also shows a discolouration, other than pink, from the growth of gram-positive organisms other than S. aureus. Using these two swabs gave a good indication of the sterility of the equipment being used in the trial. The swabs indicated that the equipment used was free from bacterial contaminants. Furthermore, swabs were taken using the milk as samples. Again, the swabs showed that the milk was free from bacterial contaminants at the beginning of the trial.

In addition, on Day 28 of the trial, the samples were also checked with both the Praecautio E. coli and S. aureus swabs. No contaminants were found in the E. coli swabs. The control samples showed a purple discolouration on the S. aureus swabs, whereas the trial swabs showed little or no discolouration. This indicates that the yogurt-making process (pasteurization) as well as the antibacterial additives ensured the yogurt remained free from bacterial-type contaminants.

pH and Syneresis

The pH of milk is generally considered to be just below neutral, between 6.4 and 6.8 [23], and according to Kroger [24], the optimal pH of yogurt is 4.1. After 4 days of inoculation with LAM, the pH was 4. It continued to drop to 3.81 by the end of the trial. These are consistent with the pH levels expected in yogurt.

In a trial conducted by Ziarno and Zareba [15], the percentage of syneresis in the trial samples ranged between 21.6 and 30.9 at 28 days. This was attributed to “the step in the production process at which mTGase was added to milk.” In this trial, mTGase was added 12 hours prior to fermentation. In the trial presented in this paper, the mTGase was added at the same time as fermentation started - which appears to be a reasonable explanation for the percentage syneresis being higher (around the 50% mark) than that reported by Ziarno & Zareba [15]. Because of the interrupted refrigeration regime, all the additives had to be added at the same time as fermentation started, otherwise natural, uncontrolled fermentation would have occurred - nullifying the result. For this reason, adding ingredients 12 hours prior to fermentation would not be recommended as a production procedure for the Eritrean yogurt producers. Even so, the physical attributes (see “Taste and aroma development” below) of the yogurt were considered suitable.

Taste, aroma and physical property development

According to Tortoe, et al. [25], “Congeals have been added to yogurts to improve the texture and consistency…”. They also mention that “starch congeals in yogurt improve the viscosity, texture, and mouthfeel and prevent wheying-off. Starch congeals are popular due to their advantage to thicken yogurts without adding fat and give the food a transparent, glistening sheen, creamy texture as well as ease processing at a lower cost compared to other hydrocolloids”. Wong, et al. [26] agree with the above conclusions as they also point out that starch has been widely used to increase viscosity and firmness, make the texture more appealing, and improve the mouthfeel of yogurt. Furthermore, they point out that it is cost-effective.

Putra Ramdhani and Putra Ramdhani [27] mention that with the addition of transglutaminase in yogurt, syneresis percentage was reduced while viscosity was increased. Furthermore, Gharibzahedi and Altintas [28] point out that due to crosslinking reactions with milk proteins, microbial transglutaminase improves physicochemical and textural quality properties without any negative effect on their sensory properties.

The aim of adding starch, and transglutaminase, to the yogurt culture was to improve texture and consistency (and prevent syneresis - as previously mentioned). In addition to the obvious taste and aroma qualities of the yogurt, the physical properties of the yogurt were tested and recorded.

The taste and other organoleptic attributes of the Trial samples remained unchanged (once developed) during the trial up until testing on Day 28. The trends noted in these Trial Samples corresponded with the presence of LAB as mentioned in the Microbiology results.

Although the Trial yogurt took slightly longer to develop than the Control, the additives had no adverse effect on taste, aroma, texture, and appearance. Instead, positive attributes were prolonged and the portability of the yogurt extended for more than double the time period. The addition of starch added to the positive qualities of the yogurt.

Economic and supply considerations

According to the 2022 Country Report [29], “Eritrea remains one of the world’s poorest countries, and poverty is endemic”. Because of this economic situation in Eritrea, any additional costs will have far-reaching implications. Fortunately, the concentrations used for the two antimicrobials (nisin at 1.25mg/kg and natamycin at 5mg/kg) and the starch and transglutaminase do not add significant costs to the yogurt-making manufacturing costs. The benefits of the extended lifespan that was shown far outweigh the small input costs incurred and will result in increased sales and therefore an increase in income.

Conclusion & recommendations

The trial was conducted to find suitable additives that would result in a shelf life extension of yogurt that is produced in circumstances where, due to interrupted electrical supply, consistent refrigeration is not possible - as is found in Eritrea.

The addition of native starch, nisin, natamycin, and microbial transglutaminase was shown to extend the life of yogurt produced, by more than double, using the same yogurt production procedure as employed in Eritrea yogurt-producing facilities and in similar circumstances regarding interrupted refrigeration. Furthermore, the physical attributes, as well as the taste and aroma of the yogurt were not adversely affected by the addition of the above-mentioned ingredients, but the quality of taste, aroma, texture, and other physical attributes lasted longer than the Control yogurt.

It can be concluded that under interrupted and broken cold chain conditions, the addition of the four additives in the concentrations used in this trial extends the life and quality of yogurt.

With access to laboratory testing being an additional challenge in Eritrea, it is also recommended that in-house hygiene monitoring swabs (such as the Praecautio system) be used as an economic and easy means to monitor potential contamination sources in the facilities where the yogurt is made.

This paper was produced with the financial assistance of the European Union. The contents are the sole responsibility of the authors and can under no circumstances be regarded as reflecting the position of the European Union.

Ethical considerations

The work described in this publication was commissioned by Time for Sense (an independent organisation) and implemented by GI Science Solutions (who are independent scientists). No Ethics Review Committee was therefore assigned, however, Dr. S Schneeburger did consider the ethical impact of the study and found it to be free from the potential for harm, but rather that it uplifted those impacted by it. Furthermore, at no time was any person forced to participate, but all involved did so of their own free will. In addition, the principles of anonymity and confidentiality were adhered to at all times during the study.

- Serb D. Yogurt, milk that has seen the country. courrierinternational.com; 2014 https://www.courrierinternational.com/

- Ramani M. The country that brought yoghurt to the world. bbc.com. 2018. https://www.bbc.com/

- Weill R. Yogurt, ancient food in the 21st century. (1st ed.). Danone Civil Association for Nutrition; 2017.

- Ramm A. Great Britain and the Planting of Italian Power in the Red Sea, 1868-1885. Engl Hist Rev. 1944; 59(234):214-5.

- The World Bank [Internet]. Access to electricity (% of population) - Eritrea; 2015-2021 https://data.worldbank.org/indicator/EG.ELC.ACCS.ZS?end=2021&locations=ER&start=1995&view=chart

- African Union [Internet]. Eritrea. 2021. https://au-afrec.org/eritrea

- Farag LM. The Coptic Christian Heritage: History, Faith and Culture. Routledge; 2013.

- Johnson ME. Introduction to Eastern Christian Liturgies. Liturgical Press; 2022.

- Coptic Christians [Internet]. Worldmark Encyclopedia of Cultures and Daily Life; Encyclopedia.com; [cited 2023 Mar 20]. https://www.encyclopedia.com/humanities/encyclopedias-almanacs-transcripts-and-maps/coptic-christians

- Kaplan S. Eritrea’s Economy Ideology and Opportunity. Atlantic Council African Center; 2016.

- Eritrea: The African Development Bank Board approves US$49.92 million to Build a 30 MW Solar Photovoltaic Power Plant in Dekemhare [Internet]. issu.com;. https://issuu.com/atlanticcouncil/docs/eritrea_s_economy_web_1208/4

- Saleh A, Mohamed AA, Alamri MS, Hussain S, Qasem AA, Ibraheem MA. Effect of Different Starches on the Rheological, Sensory and Storage Attributes of Non-fat Set Yogurt. Foods. 2020 Jan 7;9(1):61. doi: 10.3390/foods9010061. PMID: 31936051; PMCID: PMC7023355.

- Sreeramya K, Ramachandra, B, Praveen AR, Prabha R. Role of nisin and natamycin in dairy industry. International Research Journal of Modernization in Engineering Technology and Science. 2021; 3(11):323-7.

- Codex Alimentarius International Food Standards. General Standard for Food Additives Codex Stan 192. World Health Organization; 1995 rev. 2021.

- Ziarno M, Zareba D. The effect of the addition of microbial transglutaminase before the fermentation process on the quality characteristics of three types of yogurt. Food Sci Biotechnol. 2020; 29(1):109-19.

- Coggins C, Schilling W, Kumari S, Gerrard PD. Development of sensory lexicon for conventional milk yogurt in the United States. J Sens Stud. 2008; 23:671-87.

- Jakubowska M, Karamucki T. The effect of storage time and temperature on the quality of natural yoghurt. Acta Sci. Pol. Zootechnica. 2019; 18(4):29–38. DOI: 10.21005/asp.2019.18.4.04.

- Var I, Sahan N, Kabak B, Golge O. The effects of natamycin on the shelf life of yogurt. Department of Food Engineering, Agricultural Faculty, University of Cukurova; 2004.

- Ogden K. Nisin: A bacteriocin with potential use in brewing. J Inst Brew. 1986; 92:379-83.

- Budde BB, Jakobsen M. Real-time measurements of the interaction between single cells of Listeria monocytogenes and nisin on a solid surface. Appl Environ Microbiol. 2000 Aug;66(8):3586-91. doi: 10.1128/AEM.66.8.3586-3591.2000. PMID: 10919824; PMCID: PMC92188.

- Makut MD, Ogbonna A, Dalami H. An Assessment of the Bacteriological Quality of Different Brands of Yogurt Sold in Keffi, Nasarawa State, Nigeria. Journal of Natural Sciences Research. 2014; 4(4):19-22.

- Li Q, Montalban-Lopez M, Kuipers OP. Increasing the Antimicrobial Activity of Nisin-Based Lantibiotics against Gram-Negative Pathogens. Appl Environ Microbiol. 2018 May 31;84(12):e00052-18. doi: 10.1128/AEM.00052-18. PMID: 29625984; PMCID: PMC5981070.

- Helmenstine AM. What is the acidity or pH of milk?: Conditions that affect acidity [Internet]. ThoughtCo; c2022. https://www.thoughtco.com/what-is-the-ph-of-milk-603652.

- Kroger M. Quality of yogurt. J Dairy Sci. 1975; 59(2):344-450.

- Tortoe C, Akonor PT, Ofori J. Starches of two water yam (Dioscorea alata) varieties used as congeals in yogurt production. Food Sci Nutr. 2018; 1-10.

- Wong SS, Wicklund R, Bridges J, Whaley J, Koh YB. Starch swelling behavior and texture development in stirred yogurt. Food Hydrocoll. 2020 Jan: 98:105274. doi.org/10.1016/j.foodhyd.2019.105274.

- Putra Ramdhani S, Putra Ramdhani J. Effect of transglutaminase addition to chemical, physical, and culture survivability of yogurt during storage period. E3S Web of Conferences. 2018; 67:03042. doi.org/10.1051/e3conf/20188670304

- Gharibzahedi SMT, Altintas Z. Transglutaminase-Induced Free-Fat Yogurt Gels Supplemented with Tarragon Essential Oil-Loaded Nanoemulsions: Development, Optimization, Characterization, Bioactivity, and Storability. Gels. 2022 Aug 30;8(9):551. doi: 10.3390/gels8090551. PMID: 36135262; PMCID: PMC9498499.

- Bertelsmann Stiftung, BTI 2022 Country Report — Eritrea. Gütersloh: Bertelsmann Foundation; 2022.

- Africa’s chronic power problems have escalated into a crisis affecting 30 countries. This tolls heavily on economic growth and productivity. African Infrastructure Knowledge Program. https://infrastructureafrica.opendataforafrica.org/kquobdg/africa-s-chronic-power-problems-have-escalated-into-a-crisis-affecting-30-countries-this-tolls-heavi

Article Alerts

Subscribe to our articles alerts and stay tuned.

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Save to Mendeley

Save to Mendeley