Journal of Food Science and Nutrition Therapy

Studies on some Quality Parameters of Chin-Chin Enriched with African Palm Weevil Larvae

Department Of Food Science and Technology, Obafemi Awolowo University, Ile-Ife, Osun State, Nigeria

Author and article information

Cite this as

Alimot MR, Adekunbi TK. Studies on some Quality Parameters of Chin-Chin Enriched with African Palm Weevil Larvae. J Food Sci Nutr The. 2025; 11(1): 034-041. Available from: 10.17352/jfsnt.000058

Copyright License

© 2025 Alimot MR, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.Chin-chin, a popular West African snack, is made from wheat. This study investigated the nutritional enhancement of chin-chin with African palm weevil (APW) larvae flour and different pre-processing conditions - water blanching (70 °C and 95 °C), steam blanching, sun drying, and oven drying (60 °C) on the proximate composition, antioxidant properties, mineral content, and functional properties of the enriched products.

The addition of 5% APW flour enrichment improved the nutritional profile, increasing protein content from 16.71 to 23.19%, fat content (16.48 to 28.38%), and fibre content (8.55 - 14.43%). Mineral composition was enhanced, with notable increases in calcium (1.27 - 2.35 mg/100 g), potassium (0.77 - 1.86 mg/100 g), iron (0.75 - 1.83 mg/100 g), and sodium (0.91 - 1.73 mg/100 g).

Antioxidant properties (TPC, DPPH, and MCA) were substantially improved while functional properties (water absorption capacity and swelling capacity) were temperature-dependent, peaking at 80 °C. Processing methods influenced these parameters, with steam-blanching, oven-dried APW flour yielding optimal results for nutritional retention and sensory acceptability.

Chin-chin is a widely consumed deep-fried snack in West Africa, particularly in Nigeria. It is baked or fried dough is made from wheat flour, sugar, butter, milk, and eggs, offering a sweet and crunchy texture. Despite its popularity, traditional chin-chin is primarily carbohydrate-based, with limited protein content, making it an energy-dense but nutritionally imbalanced snack [1]. As a result, there is a growing need to enhance its nutritional value, particularly through protein fortification, to address issues of malnutrition and dietary inadequacies in many African communities.

The continuous increase in population and the concomitant decrease in agricultural production have contributed significantly to the grave shortfall in edible protein availability in developing countries. This has led to widespread protein-energy malnutrition, a condition that plays a major role in illnesses and deaths in these regions. Diets in such areas are often fibre-rich but low in adequate energy and protein, making it challenging to meet nutritional needs [2]. The search for alternative, cost-effective, and protein-rich food sources is therefore critical, particularly for developing nutrient-dense foods to address protein malnutrition and provide cheaper alternatives to animal-based proteins.

Insects, long regarded as pests or nuisances, have been consumed in many cultures as a sustainable food source. In many parts of the world, they are consumed as occasional delicacies or as substitutes during food shortages caused by droughts, floods, or war [3,4]. Edible insects offer a significant nutritional advantage due to their high protein, mineral, vitamin, and energy content while being cost-effective for poor, rural communities. Their consumption has helped avert malnutrition in several instances [5].

The African palm weevil (Rhynchophorus phoenicis) is highly valued in parts of Africa for its nutritional and cultural significance. Mature larvae of the palm weevil, often considered a delicacy by the Isoko tribe in South Nigeria, are large, fleshy, and rich in fat. They are collected from palm tree trunks and traditionally prepared by frying. Despite their nutritional potentials, the African palm weevil larvae remain underutilized, with limited scientific exploration into their chemical composition and value as a food ingredient [3].

One promising approach to improving the nutritional profile of chin-chin is the incorporation of edible insects, such as the African palm weevil (Rhynchophorus phoenicis) larvae. These larvae are rich in high-quality protein, essential amino acids, healthy fats, and micronutrients like iron and zinc, which are crucial for growth and development [6]. Traditionally consumed in several African cultures, palm weevil larvae are recognized as a sustainable and environmentally friendly protein source due to their efficient feed conversion and low resource requirements compared to conventional livestock [7]. Their nutritional profile is remarkable, with high unsaturated fatty acids, fibre, and mineral content [8]. These attributes make edible insects increasingly important in addressing global food insecurity, climate change, and the rising demand for sustainable protein sources [9].

In recent years, insect-based foods have attracted global attention as sustainable high-quality protein sources both for human food and animal feed. Recent reviews show that substituting traditional protein with insect flours in baked products, snacks, and meat analogues improves both amino acid balance and functional properties such as emulsification and water retention [10]. Techniques like blanching, defatting, enzymatic hydrolysis, and fermentation reduce off-flavours, allergens, and microbial load while improving protein solubility and digestibility [11].

Recent studies have successfully incorporated insect flours from crickets (Acheta domesticus), mealworms (Tenebrio molitor), and palm weevil larvae into various matrices like bread, pasta, and snacks, demonstrating notable improvements in protein, minerals, and essential fatty acids [12]. Furthermore, pre-processing techniques such as blanching and drying are not merely preservation steps but can act as elicitors, enhancing the bioavailability of beneficial metabolites. For instance, controlled thermal processing has been shown to improve the extractability of antioxidant compounds and inactivate anti-nutritional factors, thereby augmenting the functional quality of insect-enriched foods [13]. The objective of this work is to evaluate the nutritional, functional, and sensory properties of chin-chin enriched with palm weevil larvae.

Materials and methods

Sample collection

African palm weevil larvae were sourced from Smart360 Farms Limited, a commercial insect-rearing facility located in Ogun State, Nigeria. The larvae were reared under controlled conditions in enclosed plastic boxes maintained at 25°C - 30 °C and 60% - 70% relative humidity. The rearing substrate consisted of a nutrient-rich mixture of palm stem fragments, maize meal, and yam peelings, which was replaced weekly to minimize microbial contamination and ensure optimal larval development. Adult male and female weevils were introduced into the boxes for oviposition; eggs hatched within 3–5 days, and larvae reached harvestable size after 30–40 days of feeding. Harvested larvae were immediately transported to the laboratory in ventilated containers. All larvae used in the study were healthy, uniformly sized, and free from visible damage or disease. All the chemical reagents used during the experiments were of analytical grade.

Production of dried insect flour

The larvae were manually separated from the substrate residue and thoroughly cleaned with water several times. The cleaned palm weevil larvae were manually gutted and rinsed. Blanching of insects at varying conditions (70 °C for 5min and 95 °C for 2 min) and steamed at boiling temperature (100 °C for 1min) in a steam blancher. After blanching and steaming, the larvae were divided into three portions and were subjected to drying: oven drying (60 °C for about 24 hours) and sun drying. The larvae were spread on a stainless tray and placed in trays exposed to the sun for about 18 hours. After drying, the dried larvae were milled with a blender (Model QBL 8005 Viva) into fine flour. The samples had final moisture content in the range 2.5 and 5.6% which is suitable for prolonged storage.

Production of African Palm Weevil Flour

Wheat and African palm weevil flour were mixed in a ratio of 95%:5% respectively; the mixing was done manually. First, the blended flour was put in a bowl, followed by the addition of salt and baking powder. After this, margarine was mixed evenly with it. Eggs, sugar, and other ingredients were added to make fairly stiff dough. The thick dough was rolled with a pasta cutting machine (Model 18399c, Italy) and cut into squares. The dough was deep-fried in fresh refined vegetable oil (Devon King’s, Nigeria) at 190 oC for 5 minutes using a deep fryer (Friteuse Dyona, Model 6012, France). This constant temperature was maintained to achieve the desired crisp texture and ensure consistent oil absorption across all treatment samples. The chin-chin was placed on absorbent paper to drain and cooled, after which they were packed in high-density polyethylene bags.

Proximate analysis of Chin-chin enriched samples

The moisture, crude fat, crude protein, crude fibre, and ash contents were determined using the methods of the Association of Official Analytical Chemists (AOAC) [14]. Carbohydrate content was calculated by difference using the Atwater factor.

Determination of mineral content of Chin-chin enriched samples

The minerals were extracted using the dry ashing method as described by (AOAC 930.30, 2016). One gram (1g) of each sample was weighed into glazed, porcelain crucibles, and the sample was ashed for 2 hours at 550 oC and allowed to cool. The ash was transferred into a 250 ml beaker, to which 15 ml of concentrated hydrochloric acid and 5ml of concentrated nitric acid were added. The beaker was placed on a hotplate set at 100 oC till the acid evaporated to dryness. An aliquot (10 ml) of distilled water was added to the beaker, and the sample was filtered into a 100ml volumetric flask and made up to the mark. The mineral content of the digested sample was analysed using an atomic absorption Spectrophotometer.

Determination of antioxidant Content of Chin-chin-enriched samples

The total polyphenol content of the extract was determined by the method [15]. The ability of the extract to chelate Fe2+ was determined using a modified method of Minotti and Aust (1987) by Puntel, et al. [16]. The free radical scavenging ability of the extract against DPPH (1, 1-diphenyl-2-picrylhydrazyl) using the Anisoke, et al. [17] method.

Determination of swelling capacity of wheat-insect flour

Swelling Capacity was assessed using a modified technique by Akinwumi, et al. [18].

Determination of the colour of Chin-chin enriched samples

The colour of the samples was analyzed using a smartphone-based colour analyzer app, following the method described by Pathare, et al. [19].

Sensory evaluation

Chin-chin samples were presented as coded samples to 20 panellists comprising students in the Department of Food Science and Technology, Obafemi Awolowo University. Each sample was evaluated for taste, flavour, colour, overall acceptability, using a scale of zero to nine, with nine corresponding to like extremely. The scores from the rating were subjected to analysis of variance (ANOVA).

Statistical analysis

Data obtained was subjected to Statistical Analysis of Variance (ANOVA) using SPSS Statistical Product Service Solution Version 20.0. Means were separated using Tukey’s Test at 5% significance level.

Results and discussion

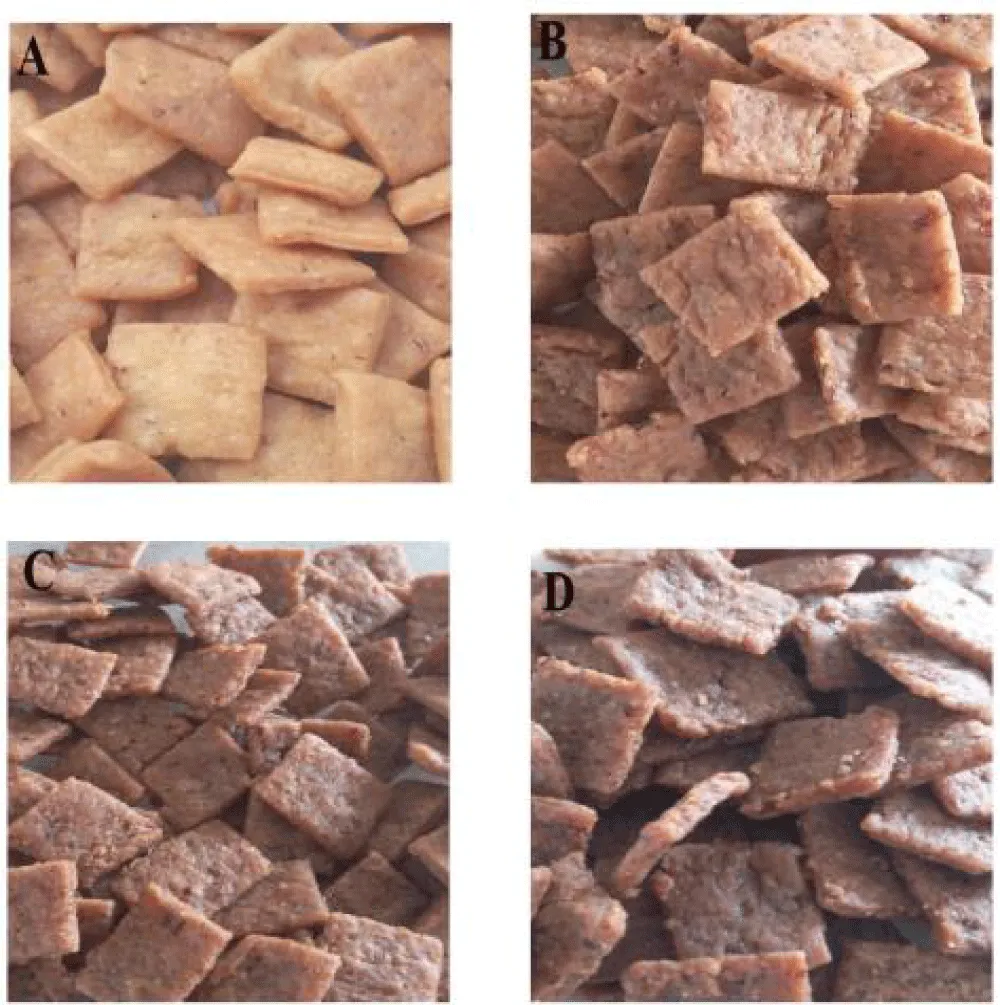

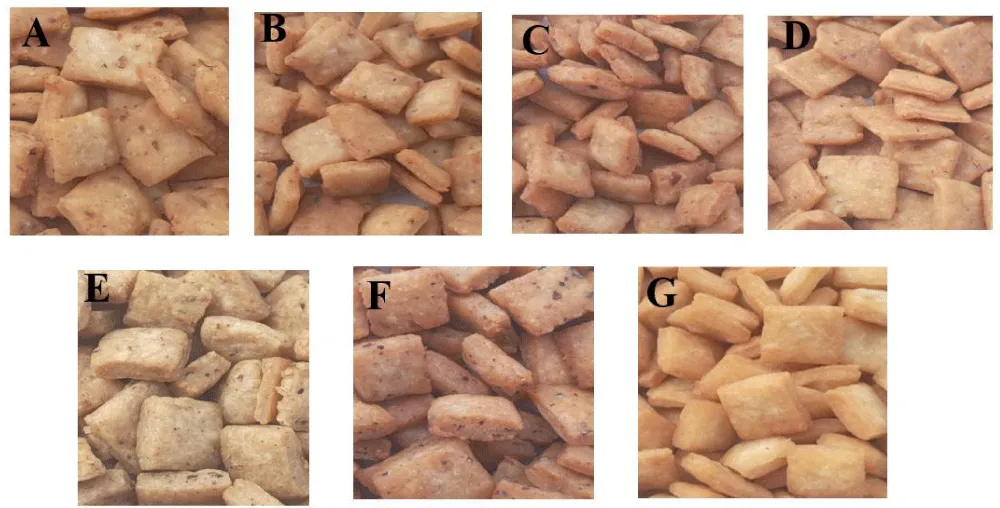

Figure 1 illustrates the physical appearance of the African palm weevil larvae after different processing conditions (blanching and drying the visual appearance of chin-chin made with palm weevil larvae flour is shown in Figure 2. The formula with a higher proportion of palm weevil flour resulted in a darker colour. As the amount of palm weevil flour increased, the lightness decreased. This can be attributed to both enzymatic and non-enzymatic browning reactions during the preparation of palm weevil flour.

Microbial safety and shelf life

The process methods employed, particularly blanching and drying, are critical for the microbial safety and shelf-life of the final product. Blanching serves as a critical thermal intervention step, effectively reducing the microbial load on the raw larvae by inactivating enzymes and destroying vegetative pathogenic microorganisms [20].

Microbial safety and shelf-life considerations. Blanching (70 °C - 95 °C) and steaming pre-treatments, followed by drying to low moisture, substantially reduced surface microbial loads and water activity; two major drivers of spoilage in insect powders and insect-enriched products. Published studies report that blanching plus controlled drying reduces total viable counts and fungal loads, and that drying to moisture <6% markedly extends the shelf life of insect flours [21]. While a full microbial shelf-life study was beyond the scope of this research, the combination of blanching and oven drying is posited to significantly enhance the product’s stability and safety compared to sun-drying, which is less controlled and poses a higher risk of post-processing contamination.

Proximate analysis of Chin-chin enriched with Palm Weevil Larvae

The proximate composition of chin-chin enriched with 5% palm weevil larvae flour (Table 1) showed that moisture content ranged between 2.74% and 5.60% with Sample B (steam blanched and sundried) having the highest moisture content value and Sample D (blanched at 70 oC and oven-dried) having the lowest moisture content value. This value agrees with the results of Ojinnaka, Emeh, and Okorie [22] for maize-wheat chin-chin enriched with palm weevil larvae, where enriched samples exhibited moisture contents ranging from 4.35% to 5.34% at 5% inclusion. The observed variations in moisture content can be explained by the processing methods applied to insect flour. Oven drying effectively reduced the moisture content, which is desirable for improved microbial stability and shelf life.

The ash content ranged between 1.23% and 1.94% with Sample A (blanched at 95 °C and sundried) having the highest ash content and Sample E (blanched at 70 °C and sundried) having the lowest ash value. The result obtained in this study is higher than the observation of Awobusuyi, et al. [23] on cookies enriched with sorghum-termite, who reported 1.7-4.2% with 10% - 50% substitutions.

The fibre content ranged between 8.55% and 14.43% with Sample A (blanched at 95 °C and sundried) having the highest fibre content and Sample F (blanched at 95 °C and oven-dried at 60 °C) having the lowest fibre content. This result is higher than those reported by Loloah, et al. and Ojinnaka, Emeh, and Okorie [22] in Tomato paste fortified with palm weevil larvae and maize-wheat chin-chin with values ranging from 3.2% - 6.6% at 8% - 30% substitution and 1.1 - 1.15 at 5% inclusion, respectively. The high fibre content is likely due to minimal structural degradation of chitin (the fibrous component of insect exoskeletons).

The protein content ranged between 16.71% and 23.19% with Sample E (blanched at 70 °C and sundried) having the highest protein content and Sample C (steam blanched and oven dried at 60 °C) having the lowest protein content. The value obtained for protein in this study is similar to those reported by Awobusuyi, et al. [23] in cookies enriched with (5-15)% sorghum-termite flour, with protein values ranging from 10.5% to 41.0%. The increase compared to the 100% wheat flour control (19.34%) is due to the high protein composition of palm weevil larvae, which contain all essential amino acids. Ekpo and Onigbinde [24] indicated that palm weevil larvae are rich in high-quality proteins.

The fat content ranged between 16.48% and 28.38% with Sample F (blanched at 95 °C and oven-dried at 60 °C) having the highest fat content and Sample B (steam blanched and sundried) having the lowest fat content. These results are within the range reported by Awobusuyi, et al. [23] in cookies enriched with (5 - 15)% sorghum-termite flour, with fat values ranging from 14.3% to 28.2%. Fat content elevation is due to the high lipid profile of palm weevil larvae (up to 40% dry weight), including beneficial unsaturated fats. High blanching may concentrate fats by reducing moisture without oxidation, while steam processing could promote minor lipid breakdown via enzyme activity [25].

The higher fat content in oven-dried samples (Sample F) can be attributed to the controlled, low-temperature (60 °C) and anaerobic environment of oven drying, which minimized lipid oxidation compared to sun drying, where exposure to sunlight and air can catalyze rancidity [25]. This preservation of lipids is crucial for maintaining the nutritional quality and sensory attributes of the product. The stability of fats during processing has been reported to indirectly influence mineral bioavailability. The nutritional functionality of insect minerals is influenced by their unique food matrix. It is suggested that the lipid component may shield minerals from binding with antinutritional factors like phytic acid [26]. Moreover, processing techniques are critical; the controlled heat from oven drying likely helps dissociate the mineral-chitin complex inherent to the insect exoskeleton. Studies confirm that such thermal processing can significantly improve mineral bioaccessibility, making minerals like calcium and iron more available for absorption [27].

The carbohydrate content ranged between 35.92% and 48.77% with Sample B (steam blanched and sundried) having the highest carbohydrate content and Sample D (blanched at 70 °C and oven-dried at 60 °C) having the lowest carbohydrate content. These results agree with the report of Awobusuyi, et al. [23] in cookies enriched with (5-15)% sorghum-termite flour, with carbohydrate values ranging from 17.2% to 54.4%. The lower carbohydrate values in insect-fortified samples compared to the control (45.83%) result from partial replacement of carbohydrate-rich wheat flour with protein- and fat-rich insect flour.

Mineral composition of Chin-chin enriched with Palm Weevil Larvae

The mineral compositions of the chin-chin samples produced are shown in Table 2 below. The calcium content of chin-chin samples ranged between 1.27 mg/100 g to 2.35 mg/100 g, with the highest value observed in sample F (blanched at 95 °C and oven-dried at 60 °C) and the lowest occurring in sample A (blanched at 95 °C and sundried). The higher calcium levels in insect-fortified samples could be attributed to the naturally high calcium content of insect exoskeletons, which are rich in chitin and associated minerals [28].

Potassium levels of chin-chin samples varied from 0.77 ± 0.01 mg/100 g to 1.86 ± 0.01 mg/100 with the highest value found in sample B ( and the lowest was recorded in sample E), blanched at 70 °C and sundried. The value obtained for potassium in this study is lower than those reported by Ukwo, et al. [29] in insect-fortified complementary food with 5.5% - 30% substitution, with potassium values ranging from 2.54 to 12.34 mg/100 g.

Iron content of chin-chin samples ranged between 0.75 ± 0.00 mg/100 g. Sample F (blanched at 95 °C and oven-dried at 60 °C) showed high iron content, and sample A (blanched at 95 °C and sundried) has the lowest iron content value. The result obtained in this study is lower than that of Ukwo, et al. [29], who reported 10.25 to 25.70 mg/100 g in insect-fortified complementary food with 5.5-30% substitutions.

Sodium content values of chin-chin samples ranged from 1.37 ± 0.01 mg/100 g to 1.73 ± 0.01 mg/100 g. The results obtained in this study are lower than those reported by Ukwo, et al. [29] in insect fortified complementary food with 5.5% - 30% substitutions, with values ranging from 8.12 - 27.15 mg/100 g. The relatively low variation among samples could be due to sodium’s stability during different drying processes.

Antioxidant analysis of Chin-chin enriched with Palm Weevil Larvae

The Antioxidant properties of the chin-chin samples produced are shown in Table 2 below. The result of the total phenol content of chin-chin samples ranged between 2.99 mg GAE/g and 6.74 mg GAE/g. Sample F (blanched at 95 °C and oven-dried at 60 °C ) has the highest phenolic content, and Sample D (blanched at 70 °C and oven-dried at 60 °C) has the lowest phenolic value. These results agree with the results of Gumul, et al. [30] for nut bars enriched with edible insect flours, where phenolic content increased with insect inclusion due to the bioactive compounds in insects.

The results of DPPH scavenging activity of chin-chin samples showed that DPPH radical scavenging activity ranged between 15.80% and 33.01% in the enriched chin-chin samples. Sample C (steam blanched and oven dried at 60 °C) had the highest DPPH activity, while sample E (blanched at 70 °C and sundried) had the lowest DPPH value. These results agree with the results of Rocchetti, et al. [31] for beef burgers enriched with insect powders, where DPPH scavenging increased with inclusion due to antioxidant peptides in insects.

The results of the metal chelating activity of chin-chin samples showed that metal chelating activity ranged between 55.88% and 84.72% in the enriched chin-chin samples. Sample A (blanched at 95 °C and sundried) has the highest metal chelating activity, while sample F (blanched at 95 °C and oven-dried at 60 °C) has the lowest metal chelating value. The value obtained for metal chelating ability in this study is higher than (42.4% – 52.8%) reported by Odunlade, et al. [32], with 1% - 3% inclusion for wheat bread supplemented with leafy powder (Table 3).

Swelling capacity of wheat-african Palm Weevil Larvae Flour mix

The swelling capacity (SC) showed a temperature-dependent increase, peaking at 80 °C. The swelling capacity of wheat-insect flour ranged from 68 to 375 % as presented in Table 4. The values ranged from 68% - 91% at 50 °C to 303% - 375% at 80 °C. Sample C (steam blanched and oven dried at 60 °C) recorded the highest swelling capacity (375%), while sample F (blanched at 95 °C and oven-dried at 60 °C) exhibited the lowest swelling capacity (68%), while the 100% wheat control showed relatively lower swelling (313%). The observation of this study is not in agreement with the report of Marchini, et al. [33], who reported a value ranging from 286 to 1758% at 25% - 50% of composite flour from sorghum, tapioca, and cowpea over the temperature range. The regression equations for each of the samples are shown in Table 4. The results indicated that sample C (steam blanched and oven dried at 60 °C) is the most optimal regression model for predicting the swelling behaviour of the flour mix.

The wide variation in swelling capacity across processing methods may be attributable to differences in starch–protein–fiber matrix interactions and the chitin content of the insect flour. Chitin, a structural polysaccharide in insect exoskeletons, can limit water penetration and thus reduce swelling unless its structure is partially degraded by heat or enzymatic action. Steam blanching combined with oven drying (Sample C) may have partially disrupted chitinous structures or altered starch gelatinization, resulting in the observed higher swelling capacity (Table 5).

Colour analysis of Chin-chin enriched with African Palm Weevil Powder

The colour parameters are shown in Table 6. The L* value (lightness) ranged from 35.50 to 71.22. Sample B has the lowest L* value (35.50), suggesting a darker product, while sample G was the lightest (71.22). This indicates that the addition of African palm weevil powder at 5% reduced lightness. The a* values ranged from 7.13 for sample D to 19.43 for sample A. This could be attributed to Maillard reactions and caramelization. The b* values followed a similar trend, with sample A exhibiting the highest yellowness (33.36) and sample D exhibiting the lowest b* value (11.19).

To quantitatively assess the browning, the Browning Index (BI) was calculated using the formula: BI = [100 (x – 0.31)] / 0.172, where x = (a* + 1.75 L*) / (5.645 L* + a* - 3.012 b*) [34]. Sample F had the highest BI value of (109.61), confirming excessive browning. Sample C had a significantly lower BI of (51.41). To optimize colour acceptance in future formulations, strategies could include: using antioxidant pre-treatments, introducing a step to slightly acidify the dough by adding a food-grade acid, and optimizing frying temperature to reduce Maillard reactions (Figure 3).

Sensory analysis of Chin-chin enriched with Palm Weevil Larvae

The results of the sensory evaluation of chin-chin samples were presented in Table 7. The control sample G from 100% wheat flour has the highest score in all the sensory attributes evaluated compared to the enriched chin-chin samples. Samples C (steam blanched and oven dried at 60 °C) scored higher than other samples in taste, colour, flavour, and overall acceptability, while samples B (steam blanched and sundried) scored higher in texture. Taste and flavour scores were low in samples A (blanched at 95 °C and sundried), while sample D (blanched at 70 °C and oven-dried at 60 °C) scored lower in colour, texture, and overall acceptability.

Conclusion

The successful incorporation of African palm weevil larvae flour into chin-chin at a 5% inclusion level demonstrates a promising avenue for nutritional enhancement of traditional cereal-based snacks. The choice of pre-processing method (blanching and drying) was found to be a critical factor influencing the final product’s nutritional composition, functional properties, and antioxidant activity. The significant boost in protein, fat, fibre, and ash content confirms that APW flour is a potent nutrient-dense ingredient. The observed antioxidant activities, including DPPH scavenging and metal chelation, suggest an added functional benefit beyond basic nutrition, potentially contributing to health-promoting properties.

- Adepoju OT, Alonge OR. Nutrient composition and sensory attributes of enriched chinchin. Niger J Nutr Sci. 2020;41(2):45–52.

- Schwart J, Bryant CA, DeWalt KM, Courtney A. The cultural feast: an introduction to food and society. Brooks Cole; 2003. p. 282–283. Available from: https://openlibrary.org/books/OL18792331M/The_cultural_feast

- De Foliart GR. Insects as human food. Crop Prot. 1992;11(5):395–399. Available from: https://doi.org/10.1016/0261-2194(92)90020-6

- Adedire CO, Aiyesanmi AF. Proximate and mineral composition of the adult and immature forms of the variegated grasshopper, Zonocerus variegatus (L) (Acridoidea: Pygomorphidae). Biosci Res Commun. 1999;11(2):121–126.

- Chavunduka DM. Insects as a source of food for the African. Rhodes Sci News. 1975;9:217–220.

- Ekpo KE, Onigbinde AO, Asia IO. Pharmaceutical potentials of the oils of some popular insects consumed in southern Nigeria. Afr J Pharm Pharmacol. 2009;3:51–57. Available from: https://www.researchgate.net/publication/255548825_Pharmaceutical_potentials_of_the_oils_of_some_popular_insects_consumed_in_southern_Nigeria

- Van Huis A, Van Itterbeeck J, Klunder H, Mertens E, Halloran A, Muir G, et al. Edible insects: prospects for food and feed security. Food and Agriculture Organization of the United Nations; 2013. (FAO Forestry Paper No. 171). Available from: https://www.fao.org/4/i3253e/i3253e.pdf

- Ayensu J, Larbie C, Annan RA, Lutterodt H, Edusei A, Loh SP, Asiamah EA, et al. Palm weevil larvae (Rhynchophorus phoenicis Fabricius) and orange-fleshed sweet potato-enriched biscuits improved nutritional status in female Wistar albino rats. J Nutr Metab. 2020;2020:8061365. Available from: https://doi.org/10.1155/2020/8061365

- Akande OA, Falade OO, Badejo AA, Adekoya I. Assessment of mulberry silkworm pupae and African palm weevil larvae as alternative protein sources in snack fillings. Heliyon. 2020;6(4):e03754. Available from: https://doi.org/10.1016/j.heliyon.2020.e03754

- Sogari G, Amato M, Morrone D. Incorporation of edible insects into food products: recent developments and consumer responses. Food Qual Prefer. 2023;107:104855.

- Yi L, Lakemond CM, Steenbekkers LP. Functional properties and digestibility of processed insect proteins. Food Chem. 2022;385:132716.

- Lucas AJ, de Oliveira LM, Rocha M, Prentice C. Edible insects as a sustainable alternative in food formulations: a review of nutritional, technological, and sensory aspects. Trends Food Sci Technol. 2023;132:1–13.

- Osimani A, Garofalo C. The science of edible insects: a bridge between food science and nutrition. Curr Opin Food Sci. 2021;41:230–235.

- AOAC International. Official methods of analysis of AOAC International. 20th ed. AOAC International; 2016. Available from: https://www.scirp.org/reference/referencespapers?referenceid=3194522

- Singleton VL, Orthofer R, Lamuela-Raventos RM. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Methods Enzymol. 1999;299:152–178. Available from: https://doi.org/10.1016/S0076-6879(99)99017-1

- Puntel RL, Nogueira CW, Rocha JBT. Krebs cycle intermediates modulate thiobarbituric acid reactive species (TBARS) production in rat brain in vitro. Neurochem Res. 2005;30(2):225–235. Available from: https://doi.org/10.1007/s11064-004-2445-7

- Anosike CA, Ogbodo NE, Ezegwu AL, Ani CC, Abonyi O. DPPH (1,1-Diphenyl-2-Picrylhydrazyl) radical scavenging activity of some ethnomedicinal plants in Nigeria. Am Eurasian J Toxicol Sci. 2015;7(2):104–109. Available from: https://doi.org/10.5829/idosi.aejts.2015.7.2.9319

- Akinwumi FE, Onarinde BA, Konar S, Tucker N, Oyeyinka SA. Physicochemical properties of runner bean and its starch, with a comparison to corn starch. J Food Sci. 2025;90(7). Available from: https://doi.org/10.1111/1750-3841.70440

- Pathare PB, Opara UL, Al-Said FA. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013;6(1):36–60. Available from: https://link.springer.com/article/10.1007/s11947-012-0867-9

- Müller A, Gessner DK, Roth S, Liebisch G. Impact of different drying methods on the nutritional composition, microbial load, and color of the yellow mealworm (Tenebrio molitor L.). Foods. 2022;11(10):1453.

- Son J, Park SH, Jung HJ, You SJ, Kim BG. Effects of drying methods and blanching on nutrient utilization in black soldier fly larva meals based on in vitro assays for pigs. Animals. 2023;13(5):858. Available from: https://doi.org/10.3390/ani13050858

- Ojinnaka D, Emeh TC, Okorie SU. Evaluation of the quality of composite maize-wheat chinchin enriched with Rhynchophorus phoenicis. J Food Res. 2016;5(4):26. Available from: https://www.researchgate.net/publication/304528932_Evaluation_of_the_Quality_of_Composite_Maize-Wheat_Chinchin_Enriched_with_Rhynchophorous_phoenicis

- Awobusuyi TD, Siwela M, Pillay K. Sorghum–insect composites for healthier cookies: nutritional, functional, and technological evaluation. Foods. 2020;9(10):1427. Available from: https://doi.org/10.3390/foods9101427

- Ekpo KE, Onigbinde AO. Nutritional potentials of Rhynchophorus phoenicis (F.) larva. Pak J Nutr. 2005;4(5):287–290. Available from: https://doi.org/10.3923/pjn.2005.287.290

- Zhou C, Li B, Yang W, Liu T, Yu H, Liu S, Yang Z. A comprehensive study on the influence of superheated steam treatment on lipolytic enzymes, physicochemical characteristics, and volatile composition of lightly milled rice. Foods. 2024;13(2):240. Available from: https://doi.org/10.3390/foods13020240

- De Oliveira LM, da Silva Lucas AJ, Cadaval CL, e Mellado MS. Bread enriched with flour from cinereous cockroach (Nauphoeta cinerea). Innov Food Sci Emerg Technol. 2021;68:102636.

- Mendoza-Salazar A, Santiago-López L, Torres-Llanez MJ, Hernández-Mendoza A, Vallejo-Cordoba B, Liceaga AM, González-Córdova AF. In vitro bioaccessibility of minerals from edible insects: the role of phytic acid and tannins. Food Chem. 2021;359:12993.

- Rumpold BA, Schlüter OK. Nutritional composition and safety aspects of edible insects. Mol Nutr Food Res. 2013;57(5):802–823. Available from: https://doi.org/10.1002/mnfr.201200735

- Ukwo S, Udo M, Ekong E. Nutrient content of Rhynchophorus phoenicis and its application in complementary food formulation. Food Environ Saf. 2021;20(1):21–34. Available from: https://doi.org/10.4316/fens.2021.003

- Gumul D, Oracz J, Kowalski S, Mikulec A, Skotnicka M, Karwowska K, Areczuk A. Bioactive compounds and antioxidant composition of nut bars with addition of various edible insect flours. Molecules. 2023;28(8):3556. Available from: https://doi.org/10.3390/molecules28083556

- Rocchetti G, Zengin G, Giuberti G, Cervini M, Lucini L. Impact of in vitro gastrointestinal digestion on the phenolic bioaccessibility and bioactive properties of insect-containing beef burgers. Antioxidants. 2024;13(3):365. Available from: https://doi.org/10.3390/antiox13030365

- Odunlade TV, Famuwagun AA, Taiwo KA. Chemical composition and quality characteristics of wheat bread supplemented with leafy vegetable powders. J Food Qual. 2017;2017:2793264. Available from: https://doi.org/10.1155/2017/9536716

- Marchini M, Marti A, Tuccio MG, Bocchi E, Carini E. Technological functionality of composite flours from sorghum, tapioca, and cowpea. Int J Food Sci Technol. 2021;57(8):4736–4743. Available from: https://doi.org/10.1111/ijfs.15471

- Astiz V, Guardianelli LM, Salinas MV, Brites C, Puppo MC. High β-glucans oats for healthy wheat breads: physicochemical properties of dough and breads. Foods. 2022;12(1):170. Available from: https://doi.org/10.3390/foods12010170

Article Alerts

Subscribe to our articles alerts and stay tuned.

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Save to Mendeley

Save to Mendeley